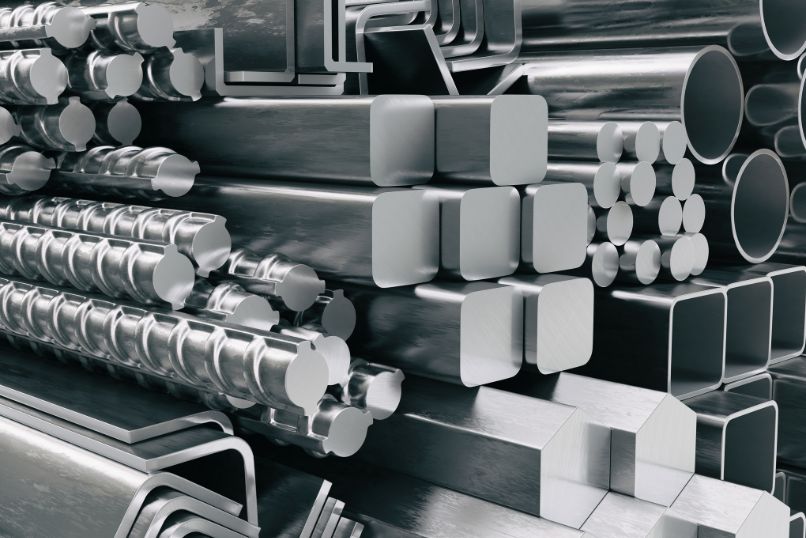

We characterize 430 stainless steel by its remarkable corrosion resistance and magnetic properties. This metal has become a staple in the automotive industry. Its application ranges from decorative trims and accessories to critical components under the hood, where durability, aesthetics, and cost-effectiveness are paramount.

Let’s look at the role of 430 stainless steel in the automotive industry and how it has revolutionized vehicle manufacturing.

Corrosion Resistance

The remarkable corrosion resistance of 430 stainless steel makes it popular for automotive manufacturing. As a ferritic stainless steel, it contains high levels of chromium (16–18 percent) and low amounts of nickel (less than 0.75 percent), making it less susceptible to rust and corrosion. This difference makes 430 stainless steel ideal for exterior trims and parts exposed to weather.

The addition of molybdenum in some variants of 430 stainless steel enhances its resistance to pitting and crevice corrosion caused by exposure to chlorides. This is common on roads due to the use of de-icing salts.

Aesthetic Benefits

Besides its functional properties, 430 stainless steel also offers aesthetic benefits. Its bright, shiny finish gives vehicles a sleek look, making it ideal for decorative trims and accessories.

With advancements in finishing techniques, such as electropolishing and passivation, 430 stainless steel can achieve a mirror-like finish that adds to a vehicle’s aesthetic appeal. This finish makes it perfect for use in high-end vehicles where appearance is a big selling point.

Cost-Effectiveness

You’ll find that 430 stainless steel is more cost-effective than other materials in the automotive industry. It is more affordable to produce because it contains low levels of nickel and other alloys, and it can reduce the overall cost of vehicle manufacturing.

This metal’s formability and weldability make it easy to work with during production. 430 stainless steel is popular among mass-produced vehicles where cost-efficiency is critical.

Under-the-Hood Applications

Vehicle manufacturers use 430 stainless steel when producing critical components under the hood. These include exhaust systems, catalytic converters, and heat exchangers.

The high-temperature strength, corrosion resistance, and low thermal expansion coefficient of 430 stainless steel make it ideal for automotive applications. It can withstand extreme temperatures and harsh environments without losing its structural integrity, ensuring the longevity and reliability of vehicle components.

The use of 430 stainless steel has revolutionized the automotive industry and plays a crucial role in producing durable, efficient, and visually appealing vehicles. As technology progresses, we can expect more advancements and applications of this remarkable material in the automotive sector.

Wieland Diversified has many options if you’re looking for a 430 stainless steel rod for your next automotive project. Contact us today to learn more about our products and services.