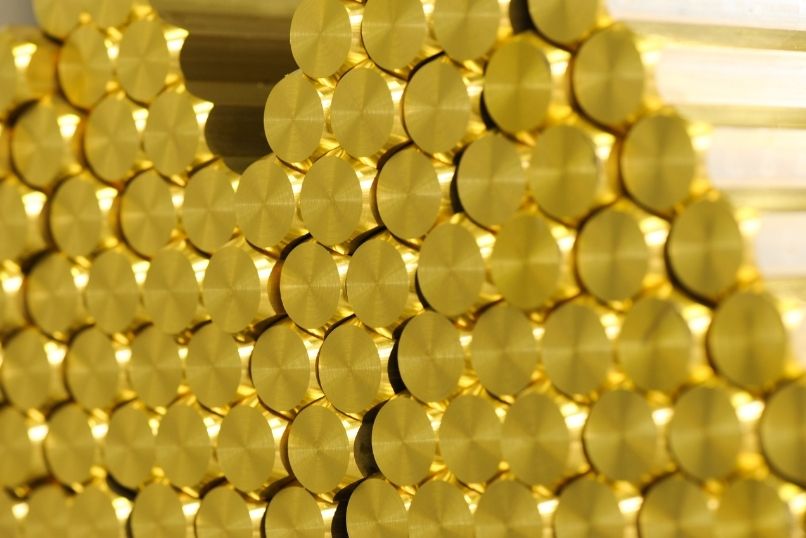

Naval brass is an alloy made up primarily of Zinc and Copper. It provides great strength and rigidity, as well as corrosion resistance. This is due to the 1% of tin it contains to prevent the dezincification process. Naval brass has high zinc content with respect to its copper content causing it to be difficult to weld. It can be highly dangerous to weld if you’re not using the correct process. Read this guide to learn how you can weld naval brass.

Naval Brass Applications

Before you can learn how to weld naval brass, it’s helpful to get an idea of the different kinds of naval brass applications that are out there. A few of them are below.

Fasteners

- Bolts

- Rivets

Aerospace

- Landing gear bushings

- Aircraft turnbuckle

Automotive

- Valve guides

- Valve Seats

Welding Naval Brass

When welding naval brass, extra precaution must be taken due to its ability to release toxic copper and zinc fumes. Using manual metal arc processes are never recommended for welding naval brass. Instead, you should use gas-shielded arc processes. Below are two methods you can consider using.

TIG

TIG stands for tungsten inert gas, better known as gas tungsten arc welding. TIG welding uses a gun to long rods to fuse two metals directly together. This process allows you to have more control and precision than other welding processes. For detail-focused processes, TIG is a great option.

MIG

MIG stands for metal inert gas, better known as gas metal arc welding. MIG has a few advantages to TIG. While they both use an electric arc to create the weld, MIG uses a feed wire that moves continuously through the gun to create a spark. MIG is a better option for large production rates because of the fact that an MIG gun is meant to run for long periods of time.

What Kind of Gas Should You Use?

When welding naval brass, you want to be sure to use an inert shielding gas. This will help protect the electrode and weld pool from becoming contaminated by oxygen. Below are a few options you have for inert shielding gasses.

- Argon

- Argon and Carbon Dioxide mix

Similar in appearance to naval brass and its welding processes, bronze casting alloys are another option. Be sure to do your research on how to weld naval brass before you begin because you want to be aware of the different welding methods you can use. Here at Diversified Metals, we can help you find the right material and correct process for all your unique applications.