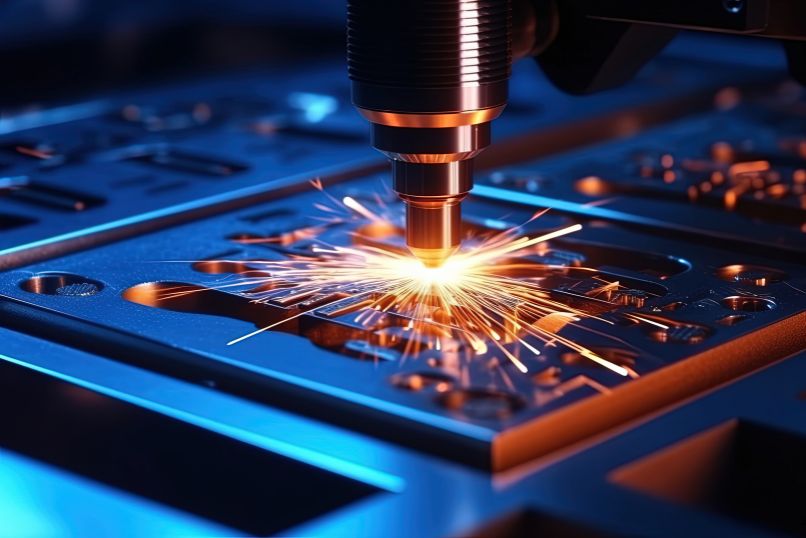

Metal fabrication has come a long way, and technological advancements have revolutionized this industry. One such development is the use of lasers in metal fabrication. Laser-cutting technology can precisely cut through thick metal sheets, producing highly accurate and consistent results.

It’s no wonder why laser cutting has become a popular metal fabrication method. Let’s explore how laser cutting adds value to the metal fabrication process.

Enhanced Precision

One of the most significant benefits of laser cutting in metal fabrication is its high precision levels. The technology uses the latest software to ensure accurate metal cutting. This accuracy ensures there is little to no wastage of material, which helps reduce costs. Laser cutting allows fabricators to cut intricate designs and shapes that would be impossible to achieve with other methods. The high accuracy and precision that laser cutting provides ensures the finished product is of the highest quality.

Increased Efficiency

Laser-cutting technology operates at high speeds; it can cut through a thick metal sheet in seconds. The speed at which laser cutting works also ensures that it is one of the most efficient metal fabrication methods. This results in faster turnaround times, which increases production and reduces lead times. In addition, the automation process of laser cutting reduces labor costs, further increasing efficiency.

Flexibility

Laser cutting can cut a wide range of metal materials, including steel, aluminum, brass, and copper. This range makes laser cutting one of the most versatile metal fabrication methods. The flexibility of laser cutting extends to design choices as well. You can create intricate and complex designs that were impossible before. Whether you need to cut intricate shapes, drill holes, or engrave patterns, laser cutting provides the flexibility to get the job done.

Reduced Material Waste

Laser cutting reduces the amount of material wasted, thanks to its highly accurate cutting process. As a result, this method of metal fabrication saves materials and reduces unnecessary expenditure. It is essential to note that reducing material wastage also means that laser cutting is an eco-friendly and sustainable metal fabrication method.

Improved Quality Control

Laser-cutting technology provides reliable quality control because of its accuracy and precision. In addition, laser-cut parts are consistent and precise, which ensures the final product is uniform and of excellent quality. The level of quality control that laser cutting technology provides will give you confidence in the product you deliver to your customers.

Laser cutting has undoubtedly revolutionized the metal fabrication industry. With high precision levels, increased efficiency, flexibility, reduced material wastage, and improved quality control, it’s no wonder why laser cutting has become a popular metal fabrication method. As a metal fabricator, you should consider incorporating laser cutting technology into your operation. The result is an improvement in quality, an increase in output, and overall cost savings. Because of these benefits, laser cutting technology provides added value to your metal fabrication process.

If you’re looking for bronze suppliers to help with your projects, Wieland Diversified can help. We specialize in providing high-quality bronze and other metal products at competitive prices and with the best customer service available. Contact us today to learn more about our products and services!